Beef Cooked Meat Mutton and Other Meat Fruits and Vegetables Automatic Slicer Vegetable Washing Line Microwave Tunnel Cooking Machine Egg Beater Pork Peeling Ma

Overview Package size per unit product 179.00cm * 72.00cm * 123.00cm Gross weight per unit product 240.000kg Product Des

Send your inquiryDESCRIPTION

Basic Info

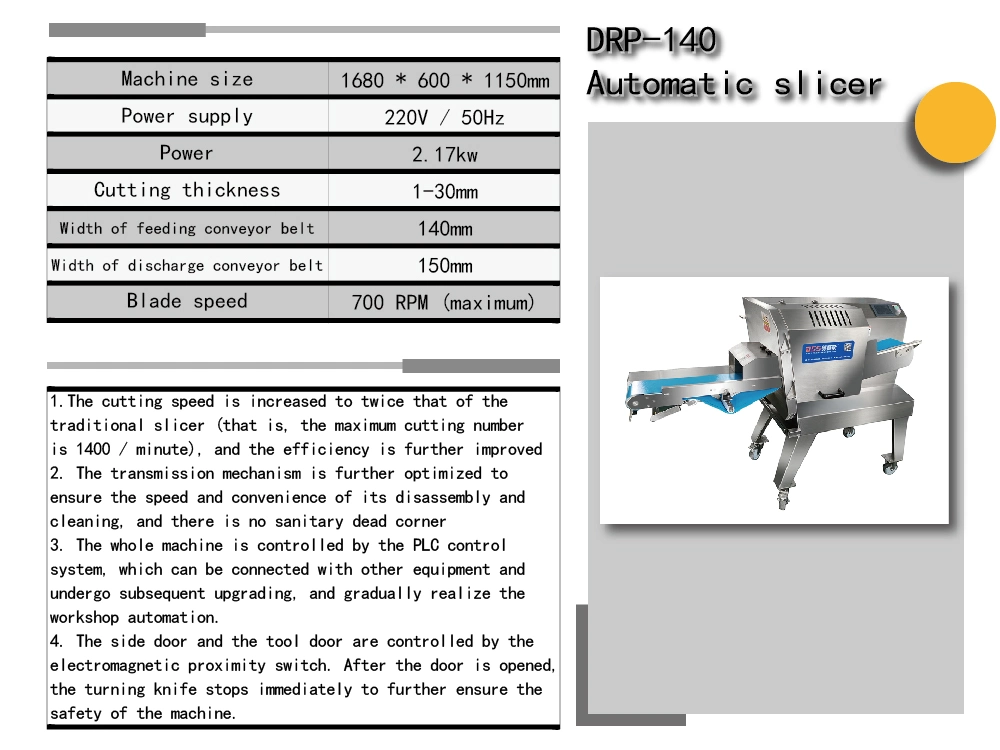

| Model NO. | DRP-140 |

| After-sales Service | One Year Warranty |

| Warranty | One Year Warranty |

| Power Source | Electric |

| Automatic Grade | Automatic |

| Type | Meat Slicer |

| Voltage | 220V |

| Customized | Non-Customized |

| Cutting Thickness | 1-30mm, Frequency Conversion Adjustable |

| Width of Feeding Conveyor Belt | 140mm |

| Width of Discharge Conveyor Belt | 150mm |

| Transport Package | Ocean Shipping/ Multiboard Packaging |

| Specification | 1680 * 600 * 1150mm |

| Trademark | DSS |

| Origin | China |

| Production Capacity | 1400rpm/ Minute |

Packaging & Delivery

Package size per unit product 179.00cm * 72.00cm * 123.00cm Gross weight per unit product 240.000kgProduct Description

| Machine size: 1680 * 600 * 1150mm Power supply: 220V / 50Hz Power: 2.17kw Frequency converter: 220V single phase Cutting thickness: 1-30mm, frequency conversion adjustable Width of feeding conveyor belt: 140mm Width of discharge conveyor belt: 150mm Blade speed: 700 RPM (maximum) |

Power supply: 220V / 50Hz

Power: 2.17kw

Frequency converter: 220V single phase

Cutting thickness: 1-30mm, frequency conversion adjustable

Width of feeding conveyor belt: 140mm

Width of discharge conveyor belt: 150mm

Blade speed: 700 RPM (maximum)Purpose:

It can cut all kinds of meat without bones, such as button meat, steak, streaky meat, cooked meat, ham, sausage, etc. into slices or blocks. It can also be used for slicing, shredding and slicing vegetables, fruits, beans and other products.

Features:

1. New tilt design to avoid material loss caused by repeated cutting;

2. The cutting speed is increased to twice that of the traditional slicer (that is, the maximum cutting number is 1400 / minute), and the efficiency is further improved;

3. The transmission mechanism is further optimized to ensure the speed and convenience of its disassembly and cleaning, and there is no sanitary dead corner;

4. The whole machine is controlled by the PLC control system, which can be connected with other equipment and undergo subsequent upgrading, and gradually realize the workshop automation.

5. The side door and the tool door are controlled by the electromagnetic proximity switch. After the door is opened, the turning knife stops immediately to further ensure the safety of the machine.

6. The conveyor belt is discharged and sorted in good order.

7. The whole machine is made of SUS304 stainless steel and durable.

Related Products

-

![Hmp 603b 509b 596b 540ba Polyoxypropylene Bisphenol-a Ether CAS 32492-61-8]()

Hmp 603b 509b 596b 540ba Polyoxypropylene Bisphenol-a Ether CAS 32492-61-8

-

![Cement Mortar Antistatic Agent Suitable for Flammable and Explosive Electrostatic Construction]()

Cement Mortar Antistatic Agent Suitable for Flammable and Explosive Electrostatic Construction

-

![Factory Supply Polyester Amine Antistatic Agent]()

Factory Supply Polyester Amine Antistatic Agent

-

![High Performance Thickener Methoxypolyethylene Glycols with CAS 9004-74-4 MPEG 350]()

High Performance Thickener Methoxypolyethylene Glycols with CAS 9004-74-4 MPEG 350